Power Project in Skopje, Macedonia

- Power Project in Skopje, Macedonia

- Power Project in Zeitz, Germany

- Services for South-West Power Station, Saint-Petersburg

- Services for CCPP ‘‘Tereshkovo’’, Moscow

- Services for Unit No.3 of “NIzhnevartovskaya’’ Power Plant

Introduction

The Combined Cycle Power Plant (CCPP “Skopje”) of special purpose company TE-TO AD in

Company TE-TO AD-Skopje was registered in

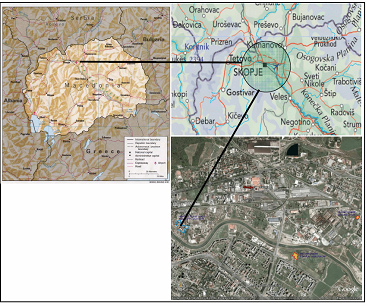

Project Location

The CCPP Skopje is constructing on the property adjacent to the existing heating plant “ISTOK” of Toplifikacija AD close to the river

|

|

|

|

|

|

Erection of ST hall and cooling tower.

August 2009 |

Erection of step up transfomer and GIS. August 2009 |

Erection of HRSG. August 2009 |

|

|

|

|

Top view of the Power Plant. January 2010 |

General view of Power Plant. October 2010 |

View of Project Site. October 2010 |

Concept of Combined Cycle Power Plant

The electrical generation capacity of the CCPP “

The plant is supplied, erected and commissioned in the framework of EPC-Contract (on “Turn Key” Basis) by the Consortium of companies “GAMA Power Systems Engineering and Contracting” (

The main systems and equipment of the CCPP “

• Natural gas supply system

• 1 gas turbine with generator

• 1 heat recovery steam generator (HRSG) with stack

• 1 steam turbine with generator

• 1 water cooled condenser system

• 1 air-water cooling tower (hybrid type) with auxiliary cooling systems

• Interconnection piping to the existing district heating system

• Process and cooling water storage and treatment systems

• Waste water treatment facilities

• Electrical equipment and high voltage switch yard

• Control and instrumentation systems (I&C)

• Civil infrastructure and buildings

The plant is based on a two shaft power train.

No bypass stack is installed and, therefore, no simple cycle operation is envisaged. All routine start-up and shutdown operations should be carried out from a central control room via a DCS control system.

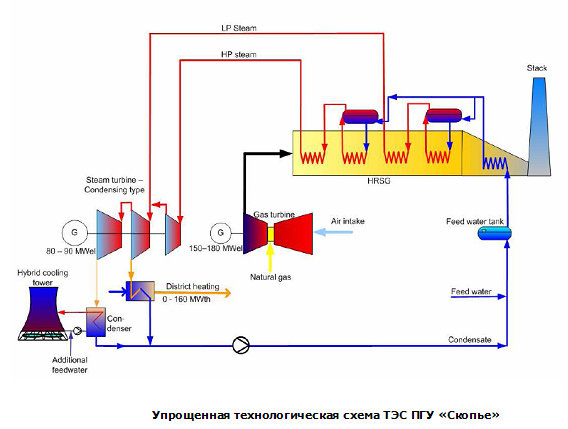

The following Figure shows a simplified process flow diagram of CCPP “

Simplified Process Flow Diagram of CCPP “

The basic plant concept consists of two power generation cycles.

The first cycle occurs in the gas turbine. Air is compressed and then passed on into the combustion chambers with a rotary compressor. Here, natural gas mixed with air is burned to produce a hot high pressure gas which is expanded through a turbine. The turbine drives both the compressor and the electrical generator to produce electricity.

The second cycle is a steam cycle. The exhaust gas from the gas turbine is still hot and is passed on into a heat recovery boiler (HRSG) where the thermal energy contained in the flue gas is used to generate steam at high pressure (approx. 100 bar). The design of this HRSG is of the natural circulation type with two pressure levels. The generated steam is used to drive a steam turbine in which additional power will be produced.

The technical concept of the Combined Cycle Power Plant utilizes cooling tower of hybrid type instead of conventional wet cooling tower. The use of this condenser is environmentally favourable due to the minimized cooling water consumption and the elimination of the fog associated with the evaporation of cooling water from the wet cooling towers.

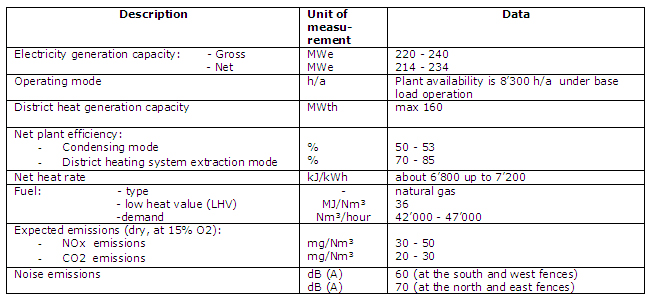

The main technical design data are summarized in the following table.

Main Technical Design Data for CCPP “

Overall Environmental Aspects

Considering all environmental and social project aspects, the national electricity generation situation of

• The plant will use natural gas as fuel which is, environmentally, the most suitable fossil fuel for power and heat generation.

• The plant will produce a considerable portion of heat energy for district heating system of Skopje city and, due to this aspect, reduce the consumption of heavy oil fuel and, consequently, emissions.

• The plant will help to meet the future rapid growth in electricity demand in Macedonia and Skopje city.

• The plant will strengthen the national and regional power supply system, reduce the national transmission power losses, stimulate industrial development and improve the living standards of the local residents.

• The project will provide employment for many workers during the construction and operation phase, as well as create the numerous indirect jobs in the supporting local services and supply industry.

• As one of the first IPP projects in Macedonia, the project will help Macedonia in attracting additional foreign investments. The know-how transfer and personnel training may also be considered as important benefits of this project.

119180, Ìîñêâà, 1-é Ãîëóòâèíñêèé ïåð. ä.1

Phone:+7 (495) 792-58-85

Fax:+7 (495) 792-58-84

info@gn-energy.com

Project: Studio DelMar, ICEngine